I just got called today by a customer looking for a buff and coat, also known as a screen and coat. Some people refer to this process as a “light sanding.” There is no such thing as a “light sanding.” A flooring professional can either sand the floor, which means sanding off the top layer of actual hardwood and getting to a fresh new layer of wood; or, they can buff the floor with a buffer machine that has been equipped with a screen, which is only a light abrading of the top layer of polyurethane and does not touch the actual wood at all.

The phrase “screen and re-coat” really describes the process of sprucing up an existing coat of polyurethane by top-coating it. As I mentioned, this is also sometimes referred to as "buff and coat" because the screen is often driven across the floor by a buffer. In order to get a new coat to adhere to the old one you must lightly abrade or ‘screen’ it. A screen is just a mesh encrusted with abrasive particles. Because it is a mesh, there are fewer abrasive particles per square inch, making it generally less aggressive than sandpaper (a 120-grit sanding screen, for example, will be less aggressive than 120-grit sandpaper).

Screens are also used under thick soft pads that further soften the cutting action of the screen. This is desirable because floor screening should only leave enough texture in the floor to allow a new coat of polyurethane to bond; screening should remove only a tiny fraction of the existing finish.

Many people are hopeful that they can get away with a buff and coat instead of a sanding. How do you know which process is right for you? Things to consider:

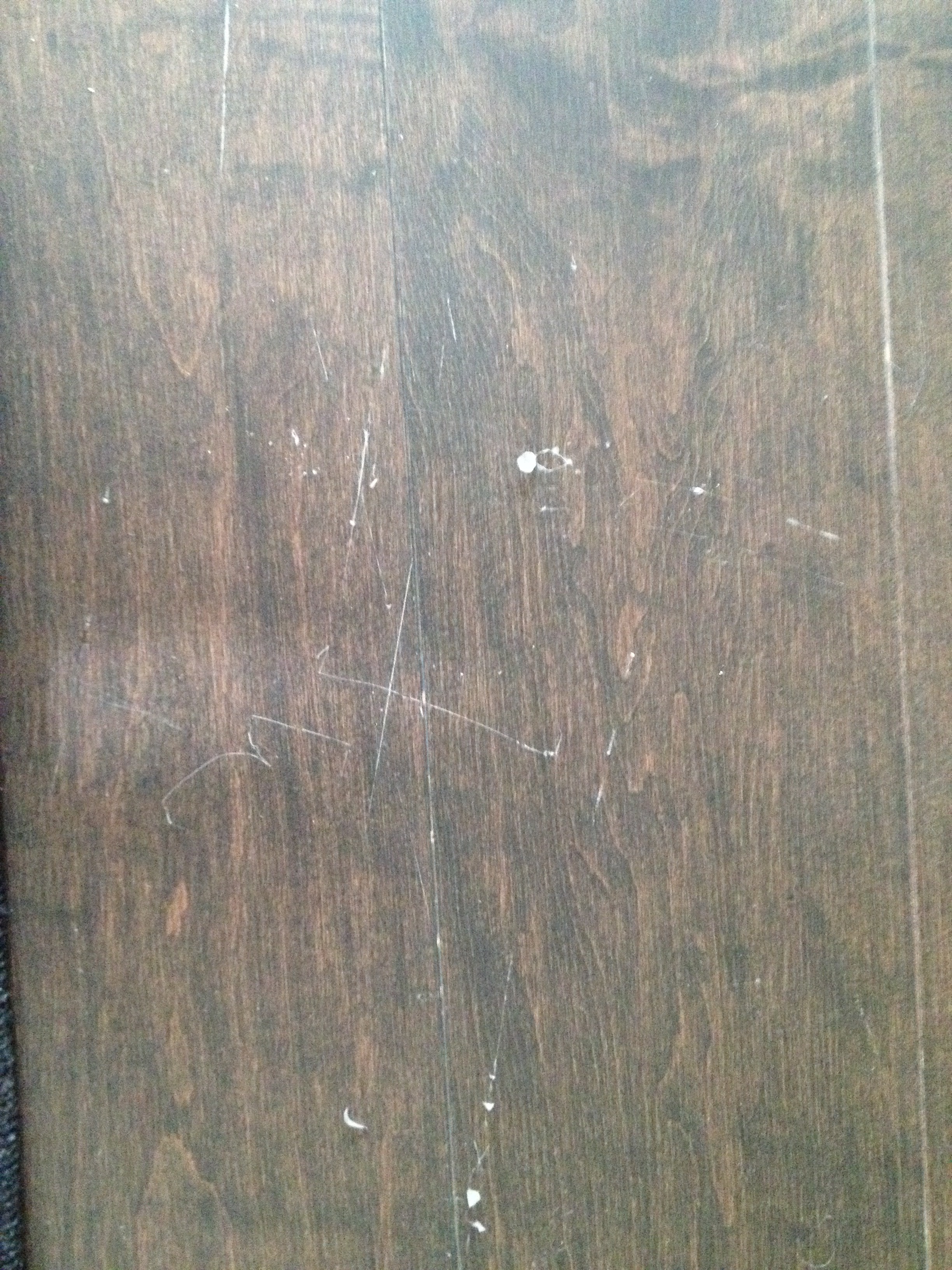

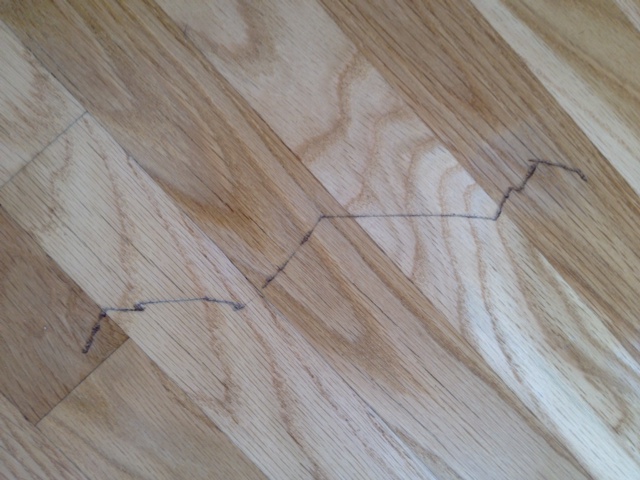

- Scratches - Surface scratches in the top layer of polyurethane only can be removed by a screen and coat, while scratches that are into the wood will not be removed. If the scratch or scratches look clear, you can probably take care of them with a buff and coat. If the scratches are light or white in color or are lighter than the surrounding wood (dark or black scratches are old ones – they are in the wood and have filled with dust/dirt!), they will need a sanding to be removed.

- Bare wood – If the hardwood floor looks greyish colored (mainly in high traffic areas), the floor will need to be sanded. The polyurethane has been worn completely away, and the wood has become discolored.

Cleaning products – Hardwood floors that have been cleaned with the dreaded Murphy’s Oil Soap, Orange Glo, Mop and Glo, or other wax cleaners cannot be re-coated. These cleaners leave behind waxy, soapy residues that are impossible to get off the floor without sanding it, and even then that makes for a lengthy and difficult floor sanding job! (See my previous blog post “7 Tips for Proper Hardwood Floor Maintenance!)

The buff and coat procedure should really be part of a regular hardwood maintenance program. A buff and coat every 3 years or so (or more frequently for floors with hard use and heavy traffic) can greatly extend the life of your hardwood floor, as it will refresh the top layer of polyurethane. Polyurethane is a sacrificial layer on top of the wood, and it functions to protect the wood underneath it. That layer of polyurethane gets thinner and more scratched each year—as it should—because its job is to keep damage away from the wood below. If you let that protective coat deteriorate for too long, it will eventually expose bare wood to assaults from shoes, pet nails, liquid spills, and dirt/grit, causing damage that can only be repaired by sanding the whole floor.

So, every few years, well before the protective coat has grown too thin, it is best to refresh it with another coat. The critical word is “BEFORE.” A floor has to be recoated before you see damage. This is a difficult concept for a lot of people because they think they are wasting money top-coating what appears to be a floor in very good condition. However, think of polyurethane like sunscreen. Sunscreen must be applied in a good, thick, even layer before skin is exposed to the sun, and it must be re-applied periodically because it wears off. Once a sunburn appears, it is too late to apply protection.

And in regards to hardwood flooring especially, protection is always less costly than the damage that results from not having it! A buff and re-coat is considerably less costly and less time consuming than doing a complete sand and refinish! If you are in the Long Island area, we would be happy to advise you on whether or not your floor could benefit from a screen and re-coat, or if it requires a complete sanding procedure.