This week we are working on some rift and quarter sawn white oak hardwood floors at a house in Asharoken, NY that is closely surrounded on both sides by water. Why is rift and quartered flooring the best choice for this home? The answer also explains why the appearance of rift and quartered wood flooring is so uniquely different than that of Plain Sawn floors!

Amazing 105-year old Quarter Sawn parquet floors we restored in the Hempstead House Mansion at the Sands Point Preserve & Conservancy, Winter 2018.

Arched Peaks of Plain Sawn

Amazing 10" Plain Sawn Country Grade White Oak installed and finished with custom Ebony/Espresso blended stain and 3 coats Bona Traffic HD water based polyurethane. Amagansett, NY.

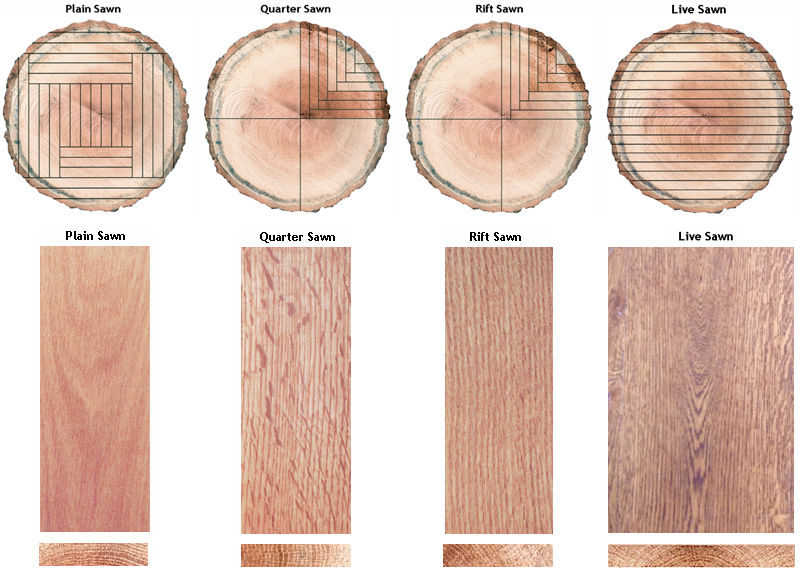

First off, let’s start with the word Sawn. Sawn is the past participle of the word saw, which is the action of sawing the tree trunk to create floor boards. The face appearance of the floor board is determined by the way the wood grain is exposed to the saw itself. What creates the wood grain? As a tree grows, it makes concentric annual growth rings, beginning in the center and moving outwards. The direction or angle of the saw cutting the log will determine the pattern/direction of how those annual growth rings (wood grain) will display on the face of the board.

Different ways to saw a log...

Notice the direction of the blade cuts will determine the way the annual rings display themselves on the face of the board.

Plain Sawn floors are the most commonly milled material today. This is the least expensive way to make wood flooring, because there is very little wasted material. Plain Sawn (aka Flat Sawn) material is made from cuts flat down the center of the log. The log is passed through the blade cutting off plank after plank without changing the orientation of the blade or the log. In plain sawing, the character markings and figures are brought out more fully, including the characteristic “Cathedral Window” grain pattern, with its dynamic flame-like peaks and arched grains.

Recent project completed in Amagansett, NY. 7" Plain Sawn White Oak installed and finished with Woca Pre-Color White + 2 coats Extra White Color Oil. Notice the dynamic arched grains and Cathedral Window pattern characteristic of Plain Sawn (Flat Sawn) material.

In Quarter Sawn flooring, the log is first quartered, and then each quarter is cut again into slices. This method also produces rift sawn flooring boards. The blade of the saw slices perpendicular to the wood’s annual growth rings, resulting in a straight, line-like grain appearance. The center boards (true quartersawn) will have growth rings positioned at 60-90 degrees to the board’s surface.

Beautiful 6" Rift And Quarter Sawn White Oak floor installed and finished with custom blended Fruitwood/Weathered Oak stain + Bona Traffic HD water based polyurethane in Oyster Bay, NY. Notice how the medullary rays feature prominently on the Quarter Sawn pieces!

In rift sawn lumber the annual rings are typically between 30-60 degrees, with 45 degrees being optimum. Rift sawn flooring is manufactured by milling perpendicular to the log’s growth rings producing a linear grain pattern with no flecking. This method produces the most waste, increasing the cost of this lumber. Rift sawn flooring is usually manufactured as a compliment to Quarter Sawn flooring, but logs can be cut specifically as Rift Sawn or Quarter Sawn flooring.

Straight grains of Rift Sawn Flooring

Installing an entirely Rift Sawn White Oak floor in West Islip. Notice the straight grain with NO Ray Fleck (Medullary Rays).

Quarter Sawing also exposes the medullary rays of the tree. Medullary rays are cellular structures found in wood, and they present very dramatically in Red and White Oak. These rays are small capillaries inside the wood that run from the center of the tree to the outer growth ring. Medullary rays grow in a radial fashion in the living tree, so while plain-sawing would cut across the rays making them invisible to the eye, quarter-sawing puts them right on the face of the board. They create a distinct, wavy ribbon-like effect on the lumber known as flecking. It is important to note that this only appears in quarter sawn floor boards. In rift sawn flooring there is no flecking effect from the medullary rays, but there is still a unique straight grain appearance on both sides of the board.

Diagram shows clearly the most prominent characteristics of the different milling cuts of flooring. Live Sawn to be discussed in a future blog post. Note the dramatic medullary ray fleck present in the Quarter Sawn piece.

The most common design is mixing the rift and quartersawn planks which helps to offset some of their increased cost as compared with plain sawn material. When flooring companies refer to quarter sawn wood, they are usually referring to a combination of quarter and rift sawn boards.

Gorgeous 4" Rift & Quarter Sawn Red Oak floor installed over radiant heat, sanded and finished with 50/50 Ebony/Weathered Oak stain and 3 coats Bona Traffic HD water based polyurethane. Note the mixing of both Rift and Quarter Sawn pieces in this floor.

Besides the unique appearance, rift and quartered wood flooring is highly prized for its stability.

In general, wood flooring adjusts to the climate that it is in by regularly absorbing and releasing moisture from the environment. This causes floor boards to expand and contract as its surrounding conditions change. Wood expands through the grain, in the direction of the curve of the annual rings. Why is that important?

A Quarter Sawn board on the left, with growth rings perpendicular to the face of the board, while on the right is a Plain Sawn board, which exhibits growth rings parallel to the face of the board.

Boards expand and contract through the annual rings.

Notice that a Plain Sawn floor will expand and contract along the sides of the board, while a Rift and Quarter Sawn board will expand up and down, which means less seasonal gapping and a floor much less prone to cupping.

When lumber is rift and quartered and sawn, any shrinkage or expansion of the lumber is greatest in thickness (as opposed to width) because the grains run perpendicular to the face of the board. For wood flooring, this means that rift and quarter sawn material is less prone to seasonal gapping, expanding/contracting, or cupping, making it very desirable for flooring. An RQ flooring board expands up and down, as opposed to side to side, as Plain Sawn floor board would. For these reasons, Rift and Quartered hardwood flooring can be used over radiant heating and in homes near the water. Homes near the water, like the one we are working on in Asharoken, have a much higher interior relative humidity than most homes and also have much more dramatic swings in conditions through the seasons. White Oak Rift and Quarter Sawn wide plank flooring is a great choice for this house, both for its stability and its style!

Asharoken, NY: Making WOCA Samples on 8" Rift and Quarter Sawn White Oak flooring, basketweave pattern. Samples from left to right are: Woca Softwood Lye, Woca Pre-Color White, Woca Driftwood Lye White, all with Woca Color Oil Extra White.