To piggyback off of my last blog post about gapping, this posting is about wood floor acclimation. Acclimation is defined as the following: the process or result of becoming accustomed to a new climate or to new conditions.

When we are planning a new wood floor installation, we have to plan for sufficient acclimation time for the wood flooring. Why do we do this?

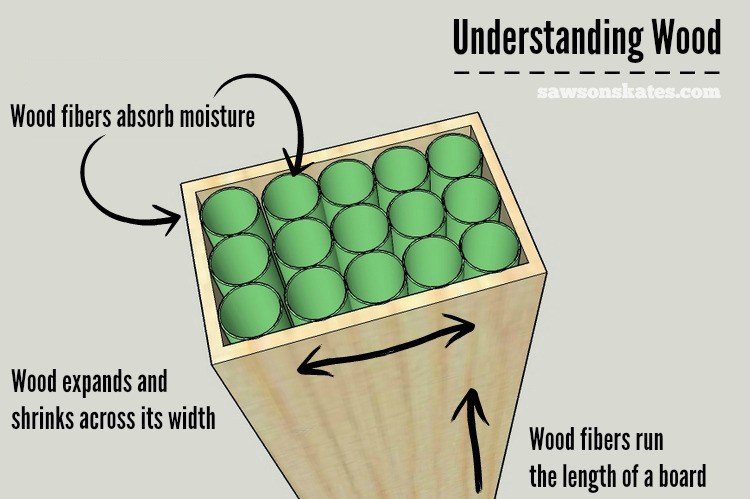

Wood is HYGROSCOPIC. A hygroscopic material is one that readily attracts water from its surroundings, through either absorption or adsorption, with the adsorbing substance becoming physically changed somewhat. When water vapor is absorbed, the water molecules are taken into the molecules of the substance, and changes such as increased volume can occur.

This is an easy-to-understand illustration of wood boards, which are hygroscopic, and how they expand and contract. Thank you, Sawsonskates!

So what are the key takeaways here for your hardwood floors?

When hygroscopic materials attract and hold water molecules from the surrounding environment, they become physically changed.

Physically changed? Think about how some of your doors get “stuck” in summer time when the air is humid. The dimensions of the door have literally increased because the moisture content of the wood has increased. The increased moisture content has caused the wood to swell, and this swelling has caused a measurable change in the size of the door - it has expanded. The same thing happens with the individual boards in your hardwood floor. With the drier and less humid air of winter, the moisture content of the wood will decrease. The cells of the wood will contract, and this causes the wood to shrink up. That same door that sticks a little bit in the summer will open just fine in the winter.

Ever notice how a paperback cover curls up in the summer or when conditions are more humid? That’s right…the paper on the inside of the cover has expanded because of the water molecules it has absorbed!

What does all of this have to do with acclimation?

If you deliver a wood floor from a climate-controlled mill into a new home in August with no working climate controls and the hardwood flooring sits there for a week, it will swell up with the increase in moisture content. The boards will be expand and swell to their fullest capacity, their greatest dimensional measurements. Then they are installed in this state. What do you think will happen once the air conditioning is turned on and the relative humidity of the home is significantly reduced? That’s right, the boards will begin to lose their high moisture content and will shrink up/contract. You will be left with gapping (spaces between floor boards) that will never completely go away.

Here’s another scenario: If you bring a wood floor from a climate-controlled mill into an unocuppied home with no heating in January and it sits there for a week, it will shrink up because the moisture content of the wood will decrease with the dry air of the environment. The hardwood floor boards will be in their most contracted state and smallest dimensions. If they are installed in this condition, what do you think can happen once it is a more humid time of year? With a big increase in moisture content, the boards may swell and expand. Since they were installed in a contracted state, this swelling can put pressure on the floor because it is now a floor literally too big for the space. This may lead to cupping, crowning, or buckling.

Acclimation is the process of conditioning your hardwood floor boards so that their naturally occurring moisture content is at or near the moisture content of the environment where they will be installed. Acclimation gives your new floor boards the proper time to adjust to the climate conditions of your home. When we install a wood floor, we want to make sure that it is not moving. That the wood has reached its equilibrium moisture content (EMC): neither losing nor gaining moisture and is stable. As reviewed earlier, installing your wood floor before it has acclimated and reached EMC can lead to a host of problems down the road as displayed in the photos above.

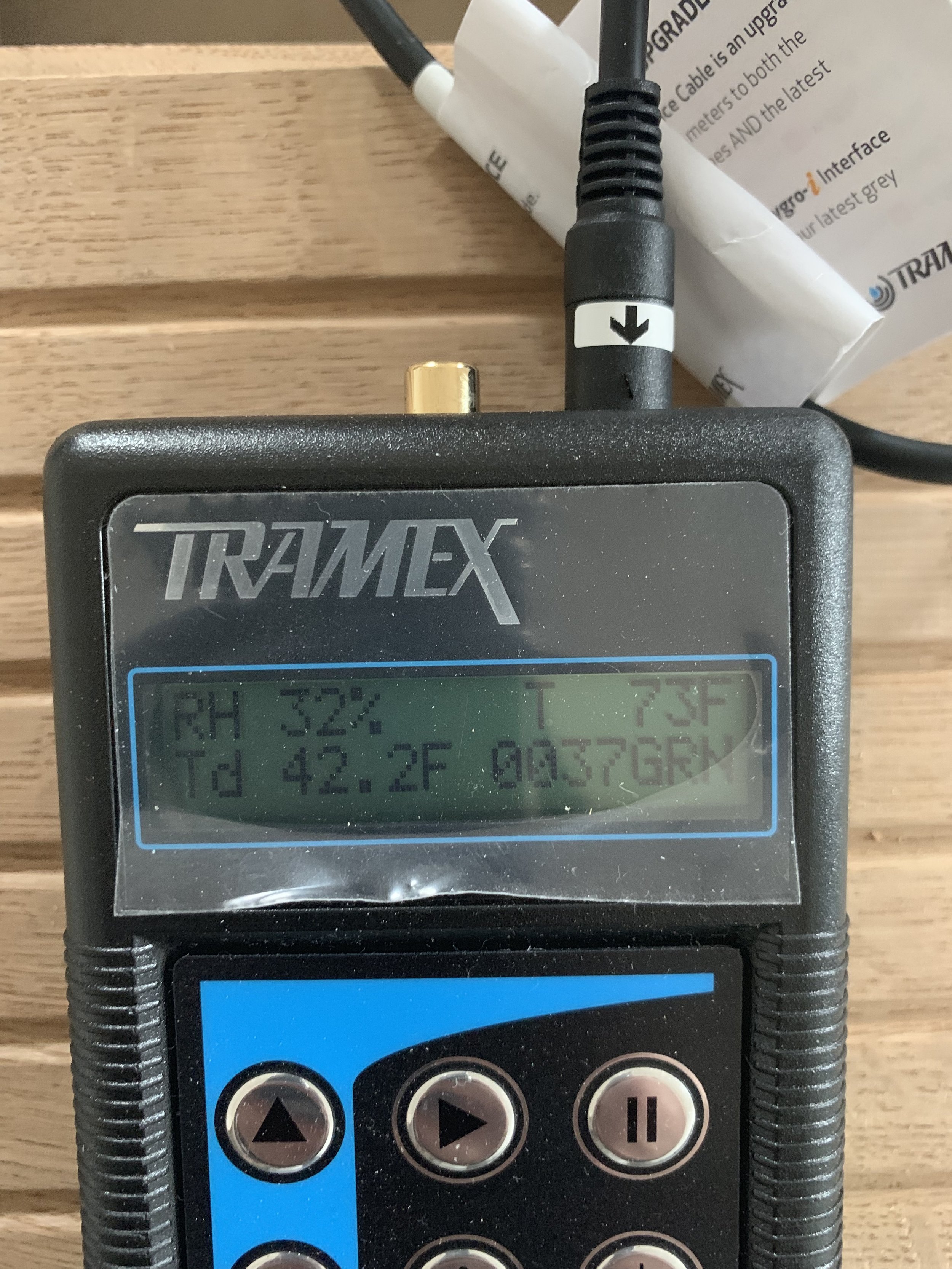

So what do we advise for proper acclimation? To start, the conditions of the home must be closed and stable. Climate controls must be on and running for at least 5 days before wood flooring arrives. If climate controls are not installed and waiting for them would hold up a construction timeline, temporary AC or heating units can be used in particular situations to mimic the conditions of a normal, occupied home, but we would strongly prefer to avoid this situation if possible. Climate controls must be on and running during acclimation, during the installation, and after the floor is installed. Remember, once you make the commitment to having wood flooring in your home, you are making the commitment to keeping the conditions stable inside your home!

The beautiful 10” Country Grade White Oak hardwood floors above are from a project we installed & finished in Amagansett in 2017. The homeowners will need to keep the house btwn 60-80 degrees and relative humidity levels at 35% - 55% if they want their floors to stay this way! Don’t forget that the wider you go with plank size, the more the boards expand and contract with environmental changes!

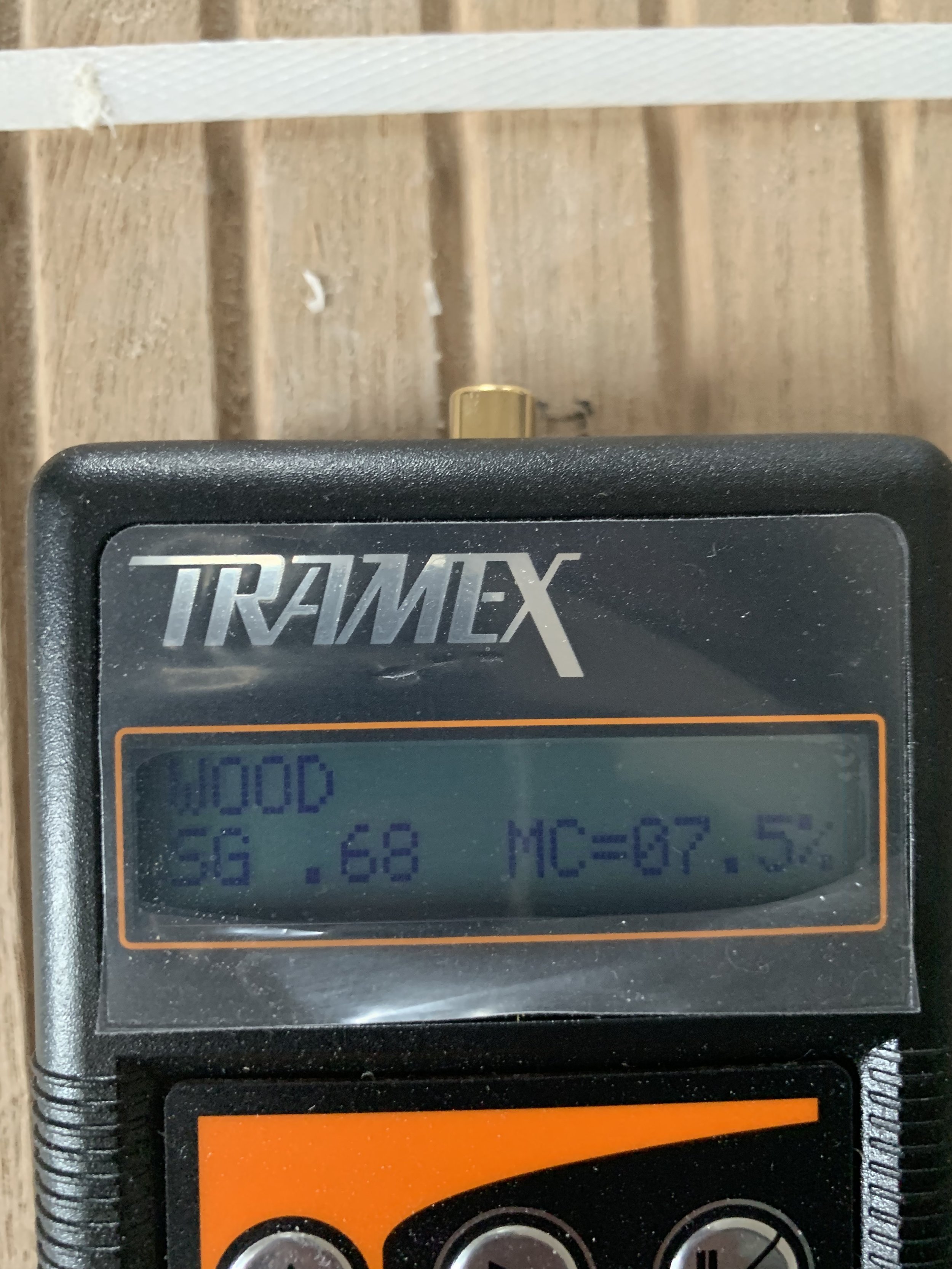

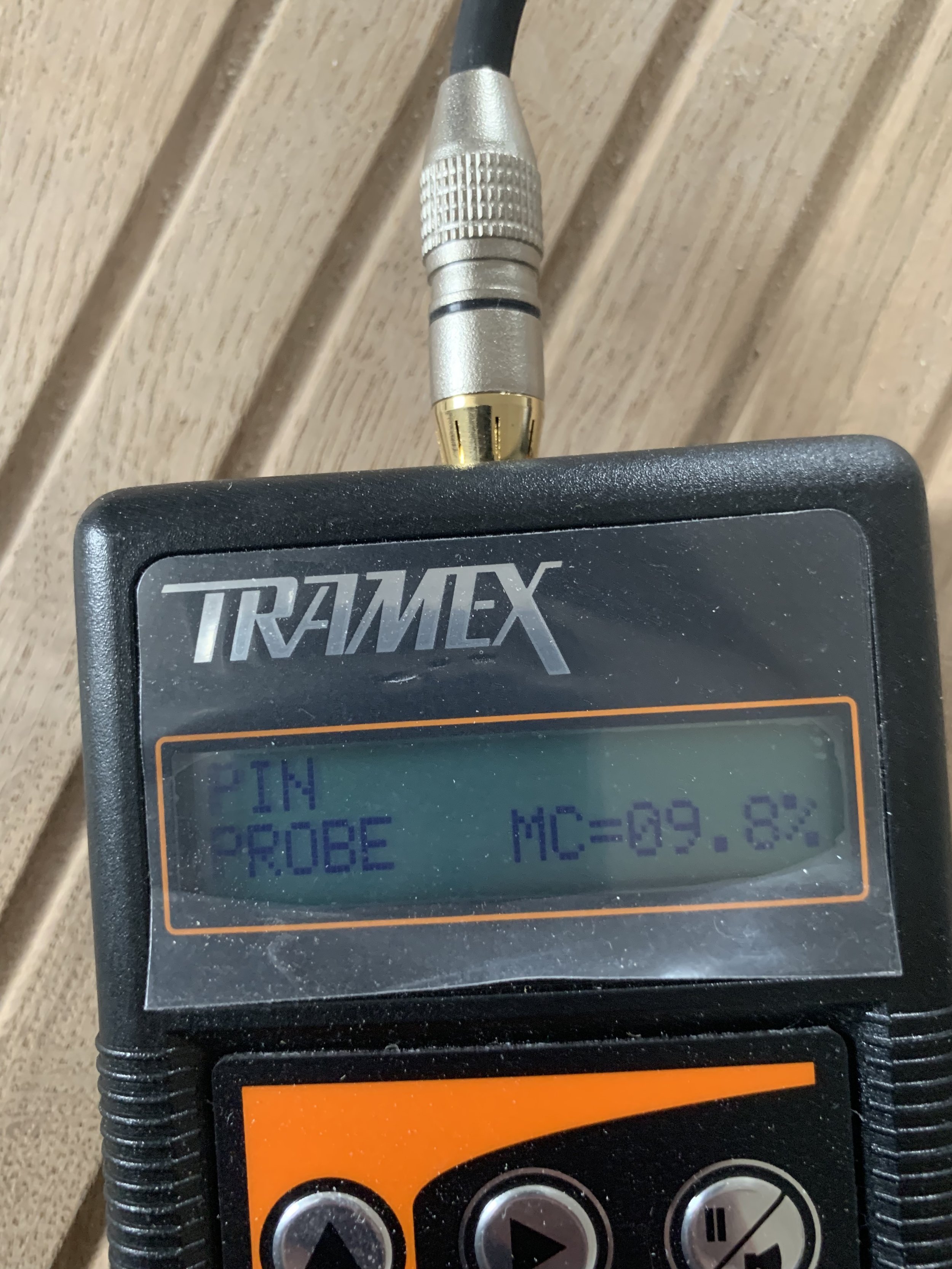

When the flooring is delivered, both the flooring and the subfloor should be tested for moisture content. Flooring should be spaced apart adequately so that air can circulate all around the boards. Remember that narrow planks “move” (expand and contract) less than wider planks. Here in the Northeast, with strip (narrower) flooring, you can stack bundles spaced about a foot apart and cross-stacked in a tic-tac-toe pattern so that air can circulate through the bundles. The wider you go with the board size, the more critical is proper acclimation! Wider planks should be stacked with spacers in between each board so that air can circulate on all sides of the boards.

Wide plank Eastern White Pine being properly acclimated

Phil Valenti stands on top of acclimating wide plank Pine for an East Hampton project we installed & finished in 2015.

Jackie atop acclimating bundles in Bridgehampton

Boss lady checking moisture content in cross-stacked bundles acclimating at a project we installed & finished in 2016.

There is no set amount of time for acclimation. Acclimation should be based on moisture content as opposed to time. Generally speaking, you can plan for roughly 3-5 days for 2 ¼” flooring and increase that time period as you go up in board size. For 10” solid Oak planks, we would recommend no less than 2 full weeks for the wood flooring to acclimate properly, and be prepared for it to take longer than that! The plywood or T&G subfloor and hardwood flooring also need to be within the acceptable range. For strip flooring, up to a 4% difference in the MC of the flooring and the wood subfloor is acceptable for installation. For wider planks, the moisture content of the subfloor and hardwood flooring should be within 2%. So again, for the question of how long for proper acclimation? As long as it takes. A few days of being delayed in the construction timeline can save you a lot of time and agony later. It’s no fun to have to empty the house of furniture after you’ve moved it all in to repair a floor that is failing.

Various moisture meters pictured above from different jobs we have done from around Long Island and over several years!

The best thing you can do to keep the relative humidity of the home from falling too low or rising too high is to put Humidity Controls on your hvac system! They really help!

In summary, acclimation is critical to the success of a hardwood floor, but continuing to monitor the climate conditions of the home after the floor is installed is equally important. With that being said, we know it is difficult to keep a home at an exactly constant relative humidity and temperature year-round. I have offered some tips for ways to do that, but a big part of having hardwood flooring is having realistic expectations for them. If you don’t make an effort to keep the relative humidity levels and temperature in your home as constant as possible, then you should expect to see more movement in your hardwood floors. To quote Hardwood Floors Magazine (published by the NWFA) from Dec 6 2016, Equilibrium moisture content is based on an “unchanging” environment. After a wood floor has been installed, changing conditions within the environment will change the equilibrium moisture content of the wood floor, ultimately resulting in dimensional change. Always remember: If you change the conditions, you change the dimensions. Embrace it…wood is wood and that is part of its charm! And if you are lucky enough to be in search of a new hardwood floor, consult with a professional on the actual job site before making your decision!

And if you don’t have an hvac system or don’t want to spend the money on fancy upgrades, use a humidifier in winter to keep the humidity levels in your home from dropping too low! It is good for your health as well!